We all spend countless hours prepping our racecars. However, many of us have another vehicle, which gets us to work, the local hardware store, to pick up the kids from school and, of course, to tow the racecar. Sure, most modern trucks are fantastically capable machines straight from the factory. But for most of us, that isn’t enough. We want to tinker, modify, and make the tow vehicle our own. In doing that, we can apply some of the knowledge we have learned from in racing efforts to our tow vehicle.

In this story, we will examine some simple items we can add to our favorite tow vehicle, which not only make it perform better, but also make it a much more enjoyable vehicle to drive on our daily ventures and something we can call “our truck.”

Without a doubt, the simplest things we can replace on our vehicles to increase power are the factory intake and exhaust systems. They typically prove to be a restrictive point in the airflow path of our engines, and installing something less restrictive nearly always proves to increase horsepower and fuel economy — which are both something we’d all love for any towing vehicle. Plus, aftermarket exhaust just sounds that much cooler.

For the first part of our install, we will focus on the intake system for our Toyota Tundra 4 x 4 with the 5.7-liter V8 engine. AEM Induction Systems is a leader in the industry, with some of the most well-thought-out products on the market today. AEM supplied us with one of its Brute Force Intake systems. Designed to eliminate much of the restrictive nature of the factory intake system, the new AEM induction system provides an additional six horsepower across the board.

Installation of the system is a snap. On a scale of one to 10 with 10 being the most difficult task requiring significant mechanical ability, I would say this installation rates a one or two.

The second item we focused on in this build was the factory exhaust system. When considering the plethora of exhaust systems we had to choose from, we kept coming back to Borla, a company widely known in the industry for making one of the highest quality exhaust systems on the market. Borla systems produce a unique tone that isn’t overly intrusive while driving, yet still frees up horsepower while also sounding fantastic. A call to our friends at Borla yielded a side-exit, cat-back dual exhaust. Why side exit? Because this is a towing vehicle of course. We want to throw those exhaust fumes out the side and not out the rear at our trailered vehicle.

Like our induction system, the Borla exhaust is another simple modification that anyone with the willingness to attempt the install can tackle with a simple set of hand tools and a little patience. Using our same scale from 1 to 10, this install would rate a two in my opinion.

Now install the new head shield using the provided hardware.

Be advised, intake noise will increase with this new system. While not overly obnoxious, some may find they actually prefer it. To get an idea what the new intake sounds like, watch this video here.

Exhaust system upgrade

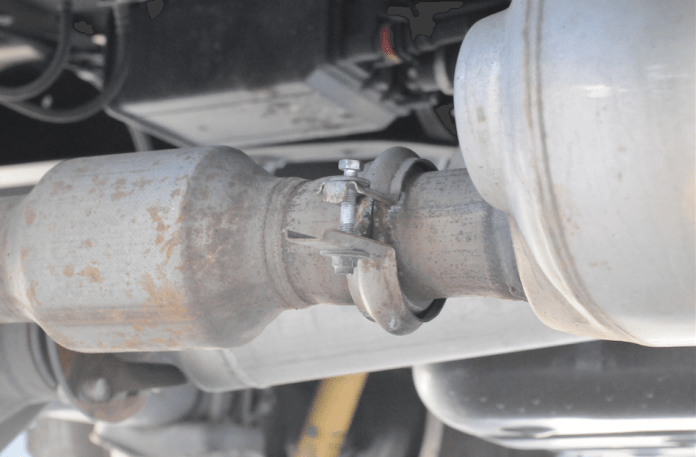

Next separate the factory exhaust system from the rubber hangers holding the muffler section to the car. Keep these so you can reuse them for the new Borla system. There is no trick here, just use WD-40 and a pry bar and pry those hangers off the system. Try to support the stock muffler section with something because it’s heavy and awkward.

Before clamping everything down, get out from under the truck and walk behind to make sure both tips line up. Adjust things at the rear to make sure they do. Then begin tightening all the clamps up starting from the rear and working your way forward finishing with the exhaust-to-catalytic converter connection bolts.

To hear how the truck sounded before and after, review this video!

What is the purpose of the small vacuum line next to the big one coming off the intake tube.